- Home

- Incinerator Accessories

- Autoloaders

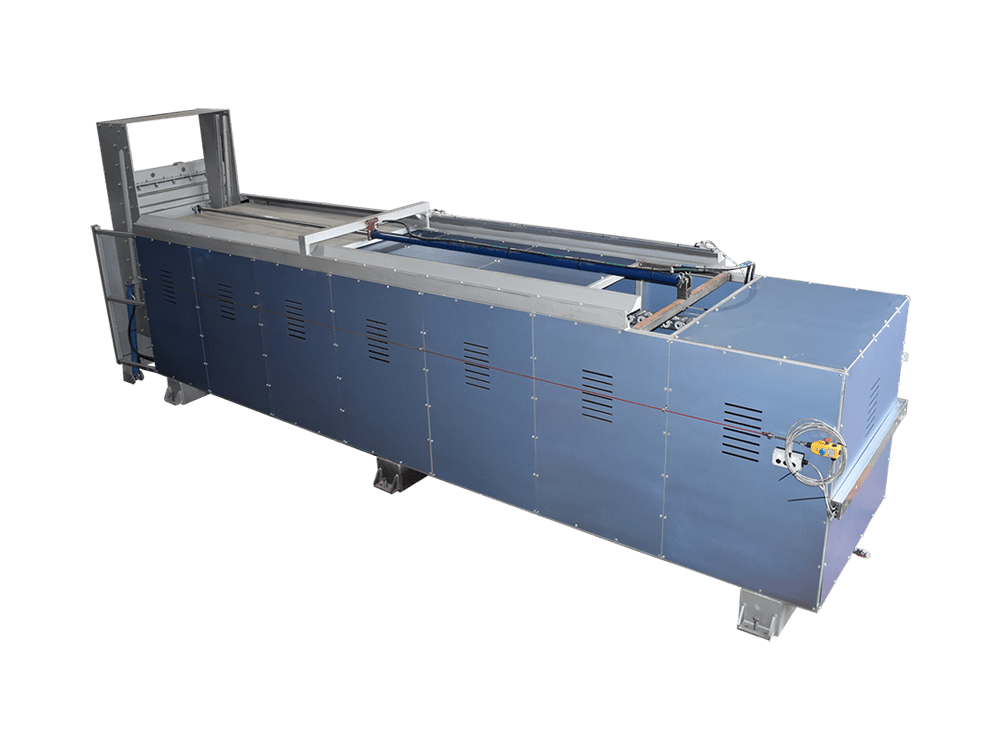

Autoloaders

Contact us for more information

This range of autoloaders are made of the highest-grade steels and manufactured by our award-winning team, recognised for their innovation and manufacturing excellence.

...so how does it work?

The chute loading mechanism is driven by a powerful hydraulic ram, delivering a measured waste load into the main combustion chamber at 750°C. This is achieved through a pre-set cycle of around 20- 30 seconds per load, creating a manged mechanical flow of waste into the incinerator.

The system is also fitted with sensors and kill switches to ensure maximum operator safety during operation.

“Autoloaders are essential in providing a continual supply of fuel (waste) into an incinerator.”

Benefits of Autoloading Waste:

- Full & powerful automation

- Optimal performance engineering

- Computer programmed and controlled

- Operational sustainability

- Predictable waste management at consistently high volumes

- Easy to operate, clean and maintain

- Direct improvement to your bottom line

Our Incinerator Autoloaders Feature:

- Full & powerful automation

- Optimal performance engineering

- Computer programmed and controlled

- Operational sustainability

- Predictable waste management at consistently high volumes

- Easy to operate, clean and maintain

- Direct improvement to your bottom line

An advanced control panel manages automation. Pre-set parameters allow you to programme the auto loader to deal with your own specific waste flows while monitoring the key parameters of temperature, pressure and time.

Packed with safety features such as 2 handed safety switch and a safety pull wire safety panelling and an amber/green light system the autoloader can be effectively run by a single, trained operator and with regular service and maintenance will drive down costs and improve the waste handling capabilities of your operation.

Hand-built in the UK

All our incinerators are hand-built in the UK by time-served welders and fabricators. Our award-winning design team are always on hand to offer their advice and technical know-how to ensure we get your project off the ground without delay.

We can also assist you in the preparation for your planning or permit application where required.